For many Singapore design and engineering teams, SOLIDWORKS is the daily workhorse: fast modelling, reliable drawings, and familiar workflows. But as projects get more complex and distributed, local teams are hitting limits around file chaos, version control, and cross-department collaboration. That’s where integration with the 3DEXPERIENCE platform comes in.

Instead of replacing SOLIDWORKS, 3DEXPERIENCE connects it to the cloud—so you can keep the desktop environment your engineers love while gaining modern data management, collaboration, and simulation workflows.

What 3DEXPERIENCE Adds to Your Existing SOLIDWORKS Setup

Think of 3DEXPERIENCE as a cloud hub that sits above your existing tools:

- Centralised data instead of scattered file servers and local folders

- Role-based apps for designers, managers, manufacturing, and quality

- Secure sharing with suppliers and customers, without emailing ZIP files

- Live dashboards for project status, tasks, and design maturity

Your engineers still model in SOLIDWORKS on their workstation, but models, revisions, and tasks are managed through the platform.

Stage 1: Connect Your SOLIDWORKS Desktop to the Platform

The first step is simple: connect the CAD tool to the cloud.

- Install the 3DEXPERIENCE add-in inside SOLIDWORKS.

- Log in with your 3DEXPERIENCE credentials.

- Start saving parts, assemblies, and drawings directly to the platform instead of local drives.

From the engineer’s point of view, the workflow feels familiar: open, save, check in/out. The difference is that every file now has a single, traceable source of truth.

Stage 2: Replace File Chaos with Structured Data Management

Once your models live on the platform, you can move beyond basic “file storage”:

- Revision control: Lock, unlock, and change maturity levels (e.g., In Work → Released).

- Built-in approvals: Route designs for review without printing or emailing PDFs.

- Secure access: Control who can view, edit, or release specific designs.

This step usually delivers quick wins for Singapore teams that previously relied on shared folders and manual version naming.

Stage 3: Bring Analysis and SOLIDWORKS Simulation into the Loop

With models and revisions under control, you can tighten the link between design and validation.

- Use SOLIDWORKS Simulation to test strength, stiffness, or thermal performance inside the familiar CAD environment.

- Store simulation setups and results alongside the 3D models on 3DEXPERIENCE for easy traceability.

- Share results with managers and non-engineers via web dashboards and lightweight viewers.

Instead of simulations living on individual workstations, they become part of a managed digital thread—from requirements to design, analysis, and final sign-off.

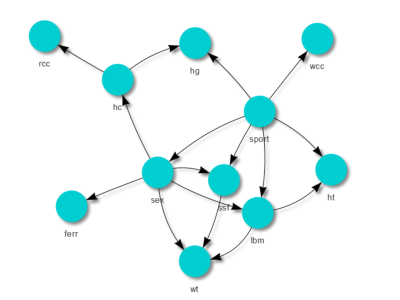

Stage 4: Collaborate Across Teams, Sites, and Suppliers

Once your core design team is comfortable with the integration, you can widen the circle:

- Invite purchasing, manufacturing, and quality teams to view or comment on models in the browser.

- Share controlled access with suppliers for specific parts or projects.

- Use tasks and issue tracking on 3DEXPERIENCE to manage changes and feedback.

Because everything is tied back to the same dataset, there’s less risk of someone working off an old STEP file or outdated drawing.

Stage 5: Build Skills with Focused Training and Change Management

Technology alone won’t transform your workflow. People and processes need to evolve too. This is where structured solidworks training singapore becomes critical:

- Intro sessions for all engineers on saving, opening, and revising via 3DEXPERIENCE

- Deeper workshops for power users on lifecycle states, simulation workflows, and issue management

- Short, role-specific training for managers, project leads, and non-CAD users

Well-planned training reduces resistance, shortens the learning curve, and helps your team use the platform as it was intended—not as a glorified cloud folder.

Practical Roadmap for Singapore Design Teams

If you’re considering this integration, you can move in deliberate, low-risk steps:

- Pilot with a single project

Connect a small, active project to 3DEXPERIENCE and keep everything else as-is. - Standardise basic rules

Define how files are named, how revisions are handled, and who approves what. - Roll out SOLIDWORKS Simulation on selected designs

Start capturing results in the platform and showing management the added visibility. - Introduce non-engineering stakeholders

Give purchasing, manufacturing, or sales controlled viewing access to reduce miscommunication. - Scale with training and feedback

Use feedback from the pilot team to refine workflows, then expand to more users and departments.

By integrating SOLIDWORKS software with the 3DEXPERIENCE platform in stages, Singapore design teams can preserve everything they value in their current CAD environment—while gaining the cloud-based collaboration, data governance, and simulation maturity they need to compete in the next decade.

Comments